Sensors for Aerospace Applications

HITEC designs and manufactures state-of-the-art force, movement, and torque sensors for civil and military aviation as well as governmental and private spaceflight programs. Our custom solutions are optimized to meet the uniquely specialized requirements of the aerospace industry, delivering on our uncompromising standards of performance, quality, and reliability.

Over the course of our 50+ year history, we have developed an exceptional range of sensor capabilities, gaining a unique insight into the aerospace industry’s demands for sensor functionality, space and weight-saving, ease of integration, reliability in extreme conditions, and meeting certification requirements. While we also provide the industry with general-purpose sensors, our greatest contribution is our ability to customize sensors to the rigorous specifications of the most vital aerospace sensor applications.

CUSTOM SENSORS FOR THE AEROSPACE INDUSTRY

Flight Controls

Dual & Single Axis Force Sensor

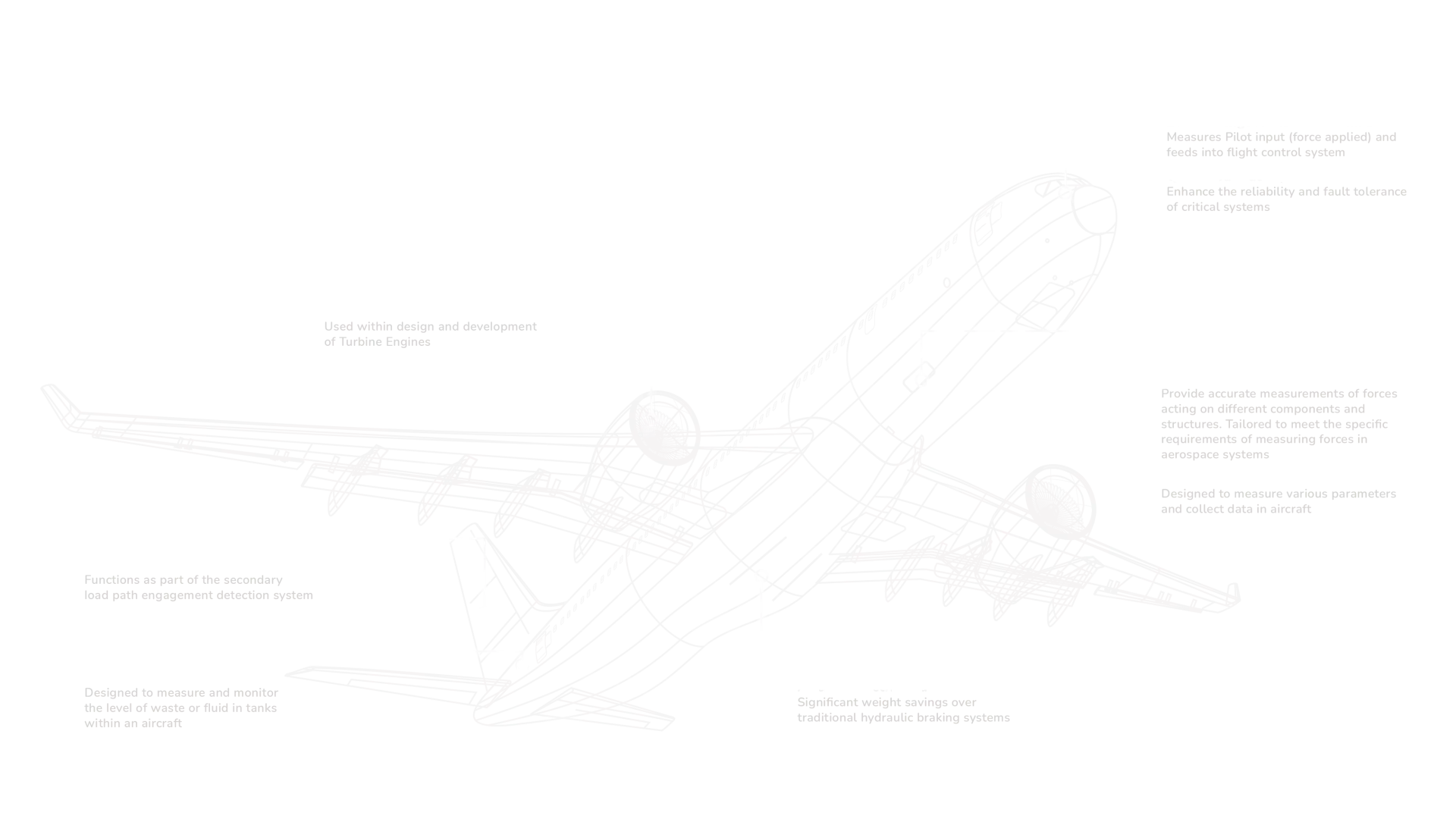

Measure Pilot input (force applied) and feeds into flight control system

Quad Redundancy

Enhance the reliability and fault tolerance of critical systems

Multi-Axis Force Sensor

Enable measurement of complex control inputs in three-dimensional space for advanced flight applications

Active Control Systems

Support real-time monitoring of pilot and system forces in active control and active parallel actuation architectures

Haptic Feedback

Provide active tactile response to pilot inputs, improving situational awareness and control precision

Airframe & Structural Integrity

Custom Load Cells

Provide accurate force measurement across aerospace components and structures. Custom-engineered to meet the performance, space, and durability requirements of specific aircraft systems

Miniature Sensors

Compact sensors designed to measure a multitude of parameters in aircraft systems where space and weight are limited

Research & Development Support

Enable aircraft design validation through structural load testing, strain measurement, and data acquisition in R&D settings

Strain Gauge Installations

Strain gauge installations for load testing to ensure structural design efficacy in lab and field environments

Flight & Field Testing

Perform instrumentation and in-situ data collection to validate aircraft modifications and monitor real-world performance

Zero Failure Benchmark

Successfully gauged fuselage with zero recorded failures, demonstrating proven sensor reliability in critical aerospace testing

Brake Systems

Aircraft Electric Brake Sensor

Large weight savings over traditional hydraulic braking systems

Compact Integration

Designed to operate within tight space constraints where every gram of system weight impacts aircraft efficiency

All-Electric Aircraft Support

Engineered to support next-generation electric aircraft architectures and braking systems

Rugged & Thermal Shock Resistant

Built to withstand harsh environments and rapid temperature changes without compromising sensor accuracy or durability

Turbine Blade Gauging

Turbine Blade Gauging

Used within the design and development of turbine engines to measure stress and strain during operational and test conditions

Field Instrumentation Services

Support blade testing and health monitoring in real-world environments with onsite strain gauge installations and data acquisition systems

Secondary Load Path Sensors

Secondary Load Path Sensors

Functions as part of the secondary load path engagement detection system

Primary-to-Secondary Load Transfer

Monitors system response when load shifts from the primary to the secondary path, typically at the rear of the aircraft

Sealed for Harsh Environments

Built with rugged, sealed designs to ensure reliable performance in extreme aerospace conditions

Continuous Level Sensors

Continuous Level Sensors

Designed to measure and monitor the level of waste or fluid in aircraft tanks

Sealed for Fluid System Integrity

Fully sealed construction ensures reliable performance in fluid and waste systems, preventing contamination or failure

Maintenance Optimization

Provides real-time feedback to indicate when servicing is required, helping optimize maintenance schedules and reduce downtime

What Sensors are used in Aerospace?

Our custom sensor designs are found on well-known flight platforms including the Airbus A220 and A350, Gulfstream G500 and G600, Embraer E170/190, and are soon to be installed on the Block 2 version of the Boeing CH-47F. They provide precise, repeatable measurement for airframe structural analysis and fatigue testing, electric actuation systems, health and usage monitoring systems (HUMS), advanced cockpit controls, and many other applications.

Our team also performs strain gauge installations and field instrumentation, supporting structural testing and validation on in-service aircraft, both in lab and operational environments.

Monitoring the fuselage of an aircraft is critical to safety and performance, our miniature sensors can be placed throughout an aircraft to provide sensory data on the health of the structure.

Our Torque Thrust Load Cell sensors provide pilots with haptic feedback from the flight control sticks to give them more information and greater control while they fly.

We specialise in providing bespoke custom strain gauge sensors for the aerospace industry to suit any application.

Apply strain gauge technology directly to your component or system and measure static and dynamic forces and loads without adding an external sensor.

WE PROVIDE FULL LIFE CYCLE END TO END CUSTOM SOLUTIONS IN HOUSE

Safer Aircraft Through expert engineering

As the aerospace industry makes increasing use of electric actuation, data-based monitoring, and standardized control systems, HITEC is the ideal partner for sensors that are available today and engineered for the long-term future.

Our experts work in direct collaboration with yours. For example, we can work with your engineers to customize best-fit sensors for your aircraft. We can come to your site to install strain gauges throughout your airframe, with all data routed to a single point for analysis. We understand certification requirements and can help you meet them for individual sensors and integrated assemblies.

We proudly operate an Aerospace Center of Excellence in Sri Lanka, featuring a cleanroom manufacturing facility dedicated to high-precision aerospace sensor production. This enables us to deliver consistent quality and scalability for programs around the globe.

We are not just a supplier, we’re a partner, committed to your long-term success wherever you design, build, and fly your aircraft. It’s a level of commitment proven in well over 65 million flight hours to date, with tens of thousands of sensors in the air around the world.

Aerospace sensor applications include

- Electrical actuators for braking and other systems

- HUMS force sensing

- Flight controls

- Cockpit controls

- Airframe fatigue test and measurement

- Control surface load detection

- Secondary load-path structures

- And many more

You’ll find off-the-shelf sensors on this website, but our greatest strength is in customizing sensor solutions to your exacting technical requirements. Contact your HITEC sales representative to discuss your needs.

HITEC'S COMMITMENT

TO EXCELLENCE, EFFICIENCY & SAFETY

HITEC has implemented a fully integrated set of management systems covering Quality, Environment and Health & Safety.

SUPPLIER OF THE YEAR

HITEC Sensors was honored with the 2023 BAE Systems Partner 2 Win Supplier of the Year Award. This prestigious recognition highlights HITEC’s outstanding commitment to operational excellence, customer satisfaction, and innovative sensor solutions that support mission-critical aerospace and defense applications.

The award is part of BAE Systems’ annual Partner 2 Win program, which celebrates suppliers who consistently deliver quality and reliability. HITEC was selected from a competitive global supply base for its excellence in meeting performance standards and exceeding expectations in delivery and service. This recognition reinforces HITEC’s role as a trusted partner to BAE Systems and underscores its dedication to advancing safety and performance in the defense industry.

HITEC is proud to contribute to high-impact projects and remains focused on continued innovation, collaboration, and quality in all aspects of its operations.