Strain Gaging and Measurement for Printed Circuit Board Applications

Printed circuit board assemblies (PCBAs) can often experience failures in the field. It is possible for heat sinks on some PCBAs to lift off the circuit board after assembly, and customers will want to figure out when and how this was happening. These PCBAs are very costly and cannot simply be scrapped. Often it is unknown if the heat sinks are lifting off the board during manufacturing, shipping or during customer install.

Stress analysis testing with strain gauges can be used to help identify the causes of component failure, but what if a customer has no experience working with strain gauges?

Our Solution

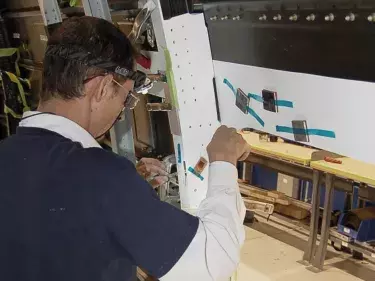

HITEC Sensors are able to work with manufacturers to place strain gauges in strategic locations on a sample lot of PCBA’s. This is done to test the stresses inflicted on a PCBA during the manufacturing process, shipment, and installation by the end-customer. Gauges are installed and PCBAs are then tested after reflow, during packaging, in a simulated transit and during an actual end-customer chassis install. In addition to performing a gauge installation, HITEC will visit the customer site and collect data during testing

The Result

Outsourcing the gauging and testing of the PCBAs to HITEC can be an economical and quick solution for any customer, with the whole process taking place within a few weeks. We review data with our customers, identify where within your processes faults are occuring due to high stresses. This allows manufacturers to quickly issue corrective actions to their end-customer, eliminating failures during specific stages of the installation process. Identifying where stresses were highest saves our customers from scrapping thousands of dollars of product.

Why Choose HITEC?

Joint Reliability and Failure PreventionPC Board strain gaging and data acquisition techniques were applied to measure solder joint reliability and component failure prevention during assembly, handling and testing operations; conforming to IPC/JEDEC-9704. |

Dynamic Strain MeasurementsDynamic strain measurements were recorded for various manufacturing sequence processes, for identifying strain and correlating to specific sequence steps. |

Moving Toward Lead-free ProductionLead-free solder alloys were utilized to increase stiffness, preventing appropriate stress distribution and more sensitive strain rate with greater potential for brittle fracture failures. |

Surface Mount Component TestingUsing HITEC’S strain gauge expertise and Instron® Test machine, Monotonic Bend Characterization per IPC/JEDEC-9702 were applied for testing surface-mount components attached to printed wiring boards. |