Would your product or system benefit from real-time, in-situ force measurement feedback, but you don’t have the space to add a sensor? Let HITEC apply strain gauges to one or more load-bearing parts to turn them into intelligent sensors...we call it transducerizing your component.

What is Transducerization?

Transducerizing is a term used in the strain gauge industry as installing strain gages directly to your product with minor mechanical modifications. This turns your product into a useable load cell. Applying strain gauge technology directly to a customer-supplied component or system allows you to measure static and dynamic forces and loads without adding an external sensor.

We can also temperature-compensate your product, minimizing temperature effects across the full range that the component will encounter. We then calibrate your gauged product, turning it into a highly accurate sensor for on-site use.

What is a Strain Gauge?

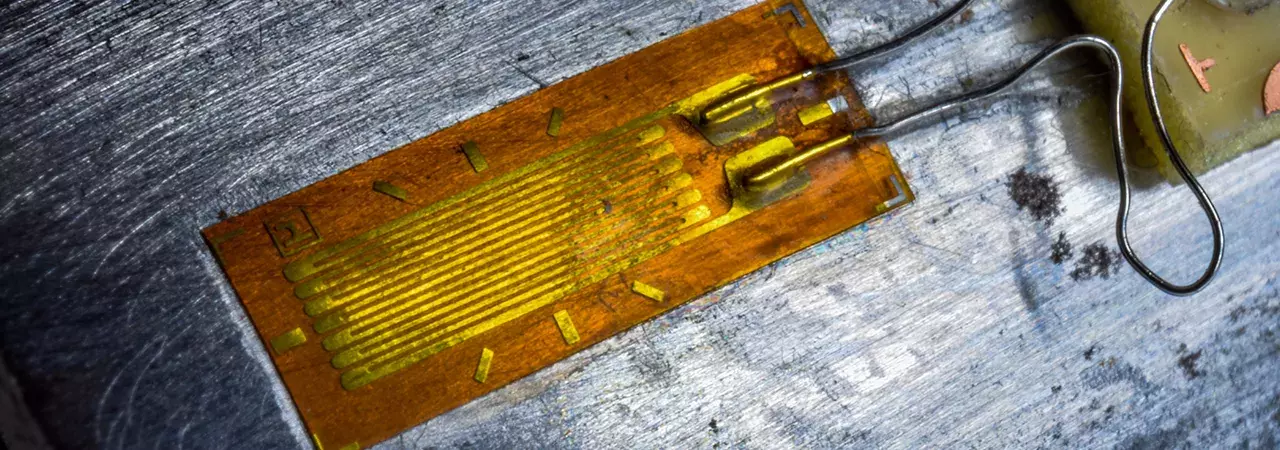

A strain gauge is a measurement device (transducer) that transforms the measurement parameter (strain) into an electrical signal proportional to strain when placed in a instrumentation system.

Close up view of an engineering strain gauge.

Benefits of Transducerization

- No change to the dynamics or structure of the test article (product or system)

- No need to worry about space or geometry

- Low cost

- High frequency response

- No added mechanical damping required due to shaft couplings

- No added adapters required as with off the shelf transducers

Transducerization in Action

A manufacturer of commercial vehicle engine braking systems needed a way to perform stress testing on engine rockers used in diesel truck engines, which are primarily used in tractor trailers that see long haul usage and mileage in excess of 1,000,000 miles. The environmental conditions were nasty, with the parts being exposed to engine oil, high temperature, and high levels of vibration. Another challenging aspect of this project was how to route the wiring so that it didn’t interfere with engine component movement and create false testing data, due to added load or drag.

HITEC are able to work with our customer’s engineering team to transducerize engine rockers by installing strain gauges in critical areas of the rockers. This is very important as engine rockers need to move freely and survive in the environment. HITEC can specify the right location, adhesive and protective coating for the specific application. Any required wiring can be done with strain relief and routed up through valve covers, this routing method does not affect the testing data in a negative way and is robust enough to handle the high engine revs and accelerated life testing on the dynamometer.

Why Choose HITEC?

Expert Team SupportA skilled team of application engineers and technician staff with an average 15 years of strain gauge technology experience |

State-of-the-Art ApproachesThe latest techniques for applications on a wide variety of surfaces |

Outstanding ProductsThe finest gauge wire and environmental coating suitable for strain measurements from cryogenic temperatures to 1800°F |

Industry Leading PartnershipsRelationships with the industry’s top strain gauge, wire, coating, connector, telemetry and data acquisition manufacturers |

Speed and QualityHigh quality, quick-turn installations to meet the most aggressive strain testing schedules |

On-site CapabilitiesOn-site machine shop and calibration capabilities |