At HITEC Sensors, we are proud to play a pivotal role in the advancement of robotic-assisted surgery, a field that has revolutionized modern medicine.

Robotic surgery systems combine cutting-edge robotics with surgical precision, enabling minimally invasive procedures that improve patient outcomes and recovery times. However, these systems face unique challenges, particularly in replicating the tactile feedback essential for delicate surgical manoeuvres.

HITEC’s multi-axis sensor solutions are engineered to overcome these challenges. Leveraging decades of experience in load cells and torque sensors, we deliver innovative, precise, and reliable solutions that enhance the performance of robotic surgical systems. Our multi-axis sensors balance weight and stiffness, while providing real-time force and torque measurements, empowering surgeons with the intuitive control needed to perform complex procedures with confidence.

HISTORY AND IMPACT OF ROBOTIC SURGERY

Robotic surgery has emerged as a transformative innovation in medicine, addressing critical challenges and delivering superior outcomes. Its journey began in the late 20th century, with early robotic systems like the PUMA 560 and the da Vinci Surgical System paving the way. These systems brought unprecedented precision, enabling surgeons to perform minimally invasive procedures that were previously impossible.

THE NEED FOR ROBOTIC SURGERY

Traditional surgical methods face several limitations. Human hands, despite their skill, lack the precision required for microscale movements. Procedures often involve large incisions, leading to longer recovery times and higher risks of complications. Robotic systems overcome these challenges by offering greater dexterity, consistency, and access to anatomically difficult regions. By combining robotics with surgical expertise, robotic surgery enhances precision, reduces invasiveness, and minimizes human error.

THE BENEFITS OF ROBOTIC SURGERY

Robotic systems offer numerous advantages:

- Minimally Invasive Procedures: Smaller incisions mean reduced blood loss, minimal scarring, and faster recovery.

- Enhanced Precision: Robots can perform sub-millimeter movements, improving outcomes in delicate procedures.

- Improved Visualization: High-definition, 3D imaging provides surgeons with better clarity and control.

- Reduced Fatigue: Robots relieve the physical strain on surgeons during lengthy procedures, maintaining accuracy throughout.

These benefits have made robotic surgery an integral part of modern healthcare.

THE CHALLENGE OF TACTILE FEEDBACK

Despite their remarkable capabilities, robotic surgical systems often lack the tactile or haptic feedback that surgeons rely on in traditional procedures. There are various reasons for this, some are system related, some are sensor related. The absence of real-time feedback makes it difficult to gauge tissue resistance or pressure, increasing the risk of inadvertent tissue damage. This limitation has spurred innovation in sensor technology to bridge the gap between robotic precision and human sensitivity.

HITEC SENSORS PIONEERING MULTI-AXIS TECHNOLOGY

As a leader in sensor technology, HITEC Sensors has developed advanced multi-axis sensors specifically designed to address the demands of robotic surgery. Our solutions integrate load cell sensors for robotic surgery alongside precision torque sensors, enabling unmatched accuracy in force and torque measurement.

By combining multi-axis load cells with high-resolution torque sensing, surgeons gain the precise haptic feedback required for delicate procedures. These sensors are engineered to detect even the slightest variations in applied force, helping to prevent tissue damage and improve surgical outcomes.

HITEC’s expertise in miniature load cells for surgical robotics ensures that our technology can be embedded in space-constrained instruments without sacrificing performance. Whether it’s measuring linear forces with load cells in robotics or capturing rotational dynamics with torque sensors, our multi-axis solutions empower the next generation of robotic surgical systems.

KEY FEATURES OF HITEC’S MULTI-AXIS SENSORS

Our multi-axis sensors deliver exceptional accuracy, enabling the precise measurement of forces and torques in real time. This precision is critical for performing micro-movements required in intricate surgical procedures.

By replicating the sense of touch, our sensors allow surgeons to "feel" the resistance of tissues through robotic systems. This enhanced feedback improves surgical control and minimizes the risk of errors.

HITEC’s sensors take into account the complete in-situ environment and are tailored to meet the unique requirements of each robotic application. From size and shape to weight and compliance. Whether for laparoscopic tools, orthopedic robotics, or other specialized systems, our sensors integrate seamlessly with existing platforms.

Designed to meet the rigorous standards of the medical field, our sealed sensors are robust, reliable, and capable of withstanding sterilization processes and other operational demands.

Subscribe for Insights

Industry insights, trends, events and unmissable content straight to your inbox

Sign up to our newsletter to get insider access to stay up to date with all things custom strain gauge sensing

APPLICATIONS OF HITEC’S MULTI-AXIS SENSORS

Our multi-axis sensors are integral to the performance of robotic surgery systems, enabling advancements in several critical areas:

Surgeons rely on tactile cues to assess tissue resistance and pressure during procedures. HITEC’s sensors provide real-time force feedback, ensuring that robotic systems offer a level of control comparable to traditional methods.

Precise calibration of surgical instruments is vital to maintaining consistency and accuracy. Our sensors enable detailed force and torque measurements, ensuring optimal performance for each procedure.

Tasks such as pulling, pressing, or rotating instruments require meticulous control. HITEC’s sensors provide multi-directional force measurements, ensuring these actions are executed with precision.

HITEC’s sensors are used in advanced training systems, replicating the tactile experiences of real-world procedures. This prepares surgeons to operate robotic systems with greater confidence and proficiency.

THE SCIENCE BEHIND MULTI-AXIS SENSORS

HITEC’s multi-axis sensors represent a pinnacle of engineering and innovation, delivering precise and reliable measurements critical to the success of robotic-assisted surgeries. Built on advanced load cell sensor technology, these systems combine multi-axis load cells with high-performance torque sensors to deliver unmatched accuracy in both linear and rotational feedback.

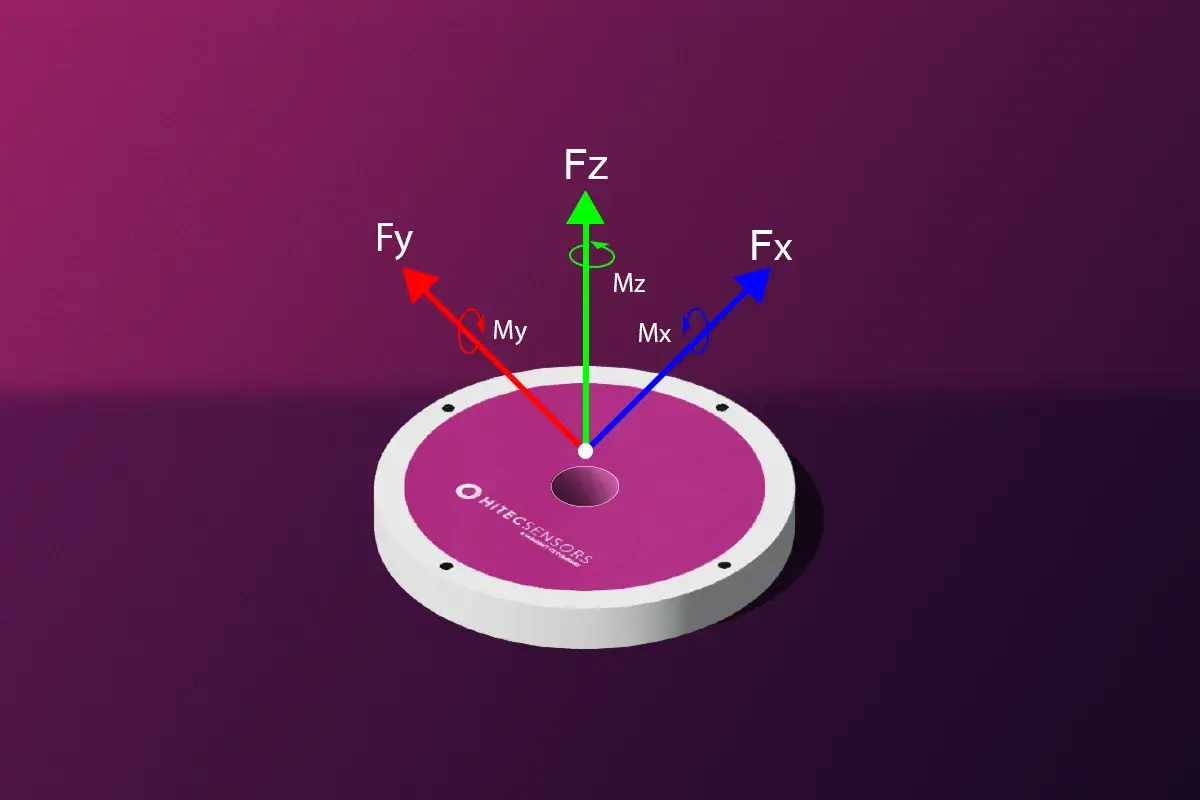

Designed to measure forces and torques across six axes, three linear (Fx, Fy, Fz) and three rotational (Mx, My, Mz), our sensors provide comprehensive real-time data that enhances the performance and adaptability of robotic surgical systems. The integration of miniature load cells for surgical robotics allows for precise force monitoring in space-constrained environments, while torque sensing ensures stability and control during complex procedures.

By uniting the capabilities of load cells in robotics with advanced torque measurement, HITEC enables surgeons to operate with greater confidence, precision, and safety in the most delicate applications.

HOW MULTI-AXIS SENSORS WORK

At their core, multi-axis sensors use advanced strain gauge sensing technologies to detect and measure force and torque in multiple directions.

Strain Gauges: HITEC Sensors uses both bonded foil and semiconductor types depending on the application. Bonded foil gauges are thin, flexible components attached to the sensor structure. Semiconductor gauges are also bonded to the structure but are typically silicon based crystals operating under a similar piezoresistive principle. When force is applied, the strain gauges deforms slightly, causing a change in electrical resistance. This change is measured and translated into calibrated data about the magnitude and direction of the force.

By integrating these technologies (foil only, semiconductor only, or a mix of the two), HITEC’s multi-axis sensors deliver unparalleled accuracy and responsiveness, ensuring that robotic systems can adapt to the intricate demands of surgical procedures.

KEY FEATURES OF MULTI-AXIS SENSORS

HITEC’s sensors measure forces (Fx, Fy Fz) and rotational moment (Mx, My, Mz) around each axis, providing a complete picture of the interactions between surgical tools and patient tissues. This multidirectional data is critical for maintaining control in complex procedures.

Designed for precision, these sensors detect micro-level changes in force and torque, enabling surgeons to make fine adjustments during delicate operations.

HITEC’s sensors deliver instantaneous feedback, allowing robotic systems to respond dynamically to changing conditions during surgery. This capability ensures consistent accuracy and minimizes delays.

Advanced onboard electronics filter, process, and condition the raw data, ensuring reliable and interference-free outputs even in challenging surgical environments.

TURNKEY SOLUTIONS FOR MEDICAL PARTNERS

HITEC Sensors offers a full suite of services to simplify sensor integration for our partners. From initial design to final calibration, our turnkey solutions streamline the production process, allowing clients to focus on their core operations while benefiting from our expertise in sensor technology.

OUR END-TO-END APPROACH FOR SUCCESS

- Material Sourcing

We select and source only the highest-quality materials to ensure sensor durability and performance. - Custom Design and Prototyping

HITEC collaborates closely with clients to develop sensors tailored to their specific in-situ needs, ensuring optimal functionality and compatibility. - Manufacturing and Calibration

Our sensors are manufactured to meet stringent qualitymedicalstandards and are fully calibrated for immediate integration into robotic systems.

This comprehensive approach has made HITEC a trusted partner for leading robotic surgery manufacturers, reducing costs and enhancing efficiency across the supply chain.

PARTNER WITH HITEC SENSORS

Robotic surgery represents the future of medicine, offering unprecedented precision and efficiency. At HITEC Sensors, we are proud to contribute to this transformative field through our advanced multi-axis sensor technology. By providing the critical feedback necessary for intuitive control, our sensors empower robotic systems to achieve their full potential, enhancing surgical precision and improving patient outcomes.

HITEC’s expertise has established us as a cornerstone in the medical sensors market. Our collaborations with global leaders in surgical robotics have yielded tangible results, including streamlined supply chains, reduced production costs, and improved manufacturing outcomes. These successes underscore our commitment to delivering unparalleled quality and innovation.

As we look to the future, HITEC remains dedicated to pushing the boundaries of what is possible in sensor technology. Through innovation, collaboration, and a steadfast commitment to quality, we are shaping the next chapter of robotic-assisted medicine and setting new standards in healthcare.

Speak to our experts

Provide us with your information and our team will contact you

George Low

George has served in many roles in his 30-year career at HITEC Sensors, including engineering, operations and sales, and is currently Vice President & Managing Director of the company. He has degrees in Marine Engineering, Business Administration and Management, with extensive experience in strain gauge technology and force sensing applications. George enjoys the commercial aspects of the business, visiting customers and understanding their applications, rolling up his sleeves and getting into the technical details to help develop solutions to the most challenging applications.