The landscape of medical implants is evolving rapidly. Devices that once served a purely structural or therapeutic role are now being enhanced with intelligent sensing capabilities. This advancement allows clinicians to monitor implant performance in real time, adapt treatment plans based on biomechanical data, and ultimately improve patient outcomes.

At the heart of this transformation are custom strain gauge sensors. By directly measuring mechanical loads and deformations during the surgery and recovery, they provide engineers and clinicians with insights that were previously inaccessible. Yet embedding sensors into implants is not a straightforward process. Engineers must contend with tight spacing constraints, harsh biological environments, stringent biocompatibility standards, and the need for absolute long-term reliability.

ORTHOPEDIC IMPLANTS

LOAD MONITORING AND LONGEVITY

Orthopedic implants operate in one of the harshest mechanical environments within the human body. Every step, twist, or lift transmits complex patterns of force through these structures. Implants equipped with custom strain gauge sensors can measure and record these forces during surgery and throughout the recovery period, providing valuable data that was previously unavailable to surgeons and engineers alike. This insight helps validate implant performance, detect early signs of loosening or misalignment, and optimize post-operative rehabilitation protocols.

Failure, whether through wear, or fracture, can be devastating and often requires complex revision surgery. Real-time measurement of load and strain during the early healing phase helps identify potential complications before they progress, ultimately improving implant success rates and patient outcomes.

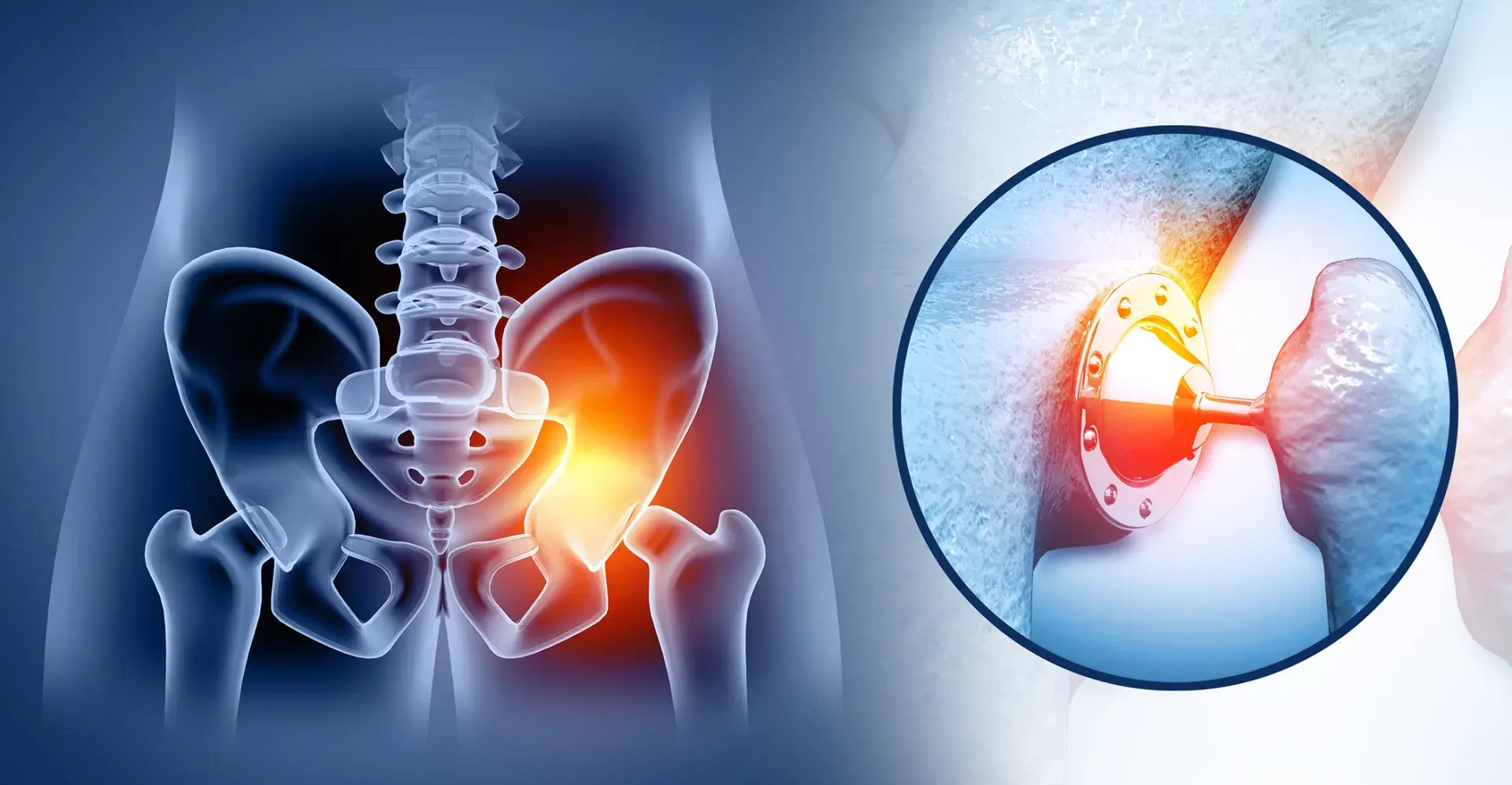

HIP IMPLANTS

TRACKING LOAD TRANSFER AND INTEGRATION

Hip implants are subjected to significant compressive and torsional stresses as they bear the full weight of the body during standing and walking. Embedding strain gauge sensors within the femoral stem or acetabular cup allows engineers to measure how forces are transferred between the implant and bone during recovery. This data helps determine whether bone ingrowth and load sharing are occurring as intended.

By understanding stress distributions in the early stages of healing, surgeons can make data-driven adjustments to rehabilitation protocols, ensuring that load transfer supports proper osseointegration and minimizes long-term loosening. Such insights also help engineers refine implant geometry and material selection for improved performance.

KNEE IMPLANTS

MEASURING ALIGNMENT AND JOINT DYNAMICS

Knee replacements face a particularly dynamic environment, with forces changing constantly across flexion, extension, and rotational movements. Strain gauge sensors embedded in knee components can track how loads are distributed across the tibial plateau and femoral condyles during movement.

These measurements provide engineers with quantitative feedback on joint alignment, ligament balance, and mechanical wear patterns. During the healing phase, they also offer valuable data for surgeons seeking to confirm proper implant function, thereby reducing the risk of instability or premature wear.

SPINAL IMPLANTS

ENSURING STABILITY UNDER CYCLIC LOADING

The spine experiences continuous cyclic loading generated by normal patient movement, even during recovery. By integrating custom strain gauge sensors into supporting structures such as rods, plates, or interbody cages, it becomes possible to monitor the mechanical forces acting along the spine throughout the healing process.

These measurements provide insight into how loads are distributed across the spinal region, offering valuable information on structural performance and tissue response. With precise strain data, engineers can validate design durability, and clinicians can quantitatively track recovery progress over time.

Subscribe for Insights

Industry insights, trends, events and unmissable content straight to your inbox

Sign up to our newsletter to get insider access to stay up to date with all things custom strain gauge sensing

ADDRESSING THE CHALLENGES

OF INTELLIGENT IMPLANTS

Across orthopedic applications, one theme is constant: the engineering requirements of implantable strain gauges are too demanding for generic solutions.

HITEC Sensors excel in this space:

- Custom Design and Co-Engineering: HITEC partners with medical device OEMs from the earliest stages of a project, ensuring that sensors are designed to match implant geometries and withstand long-term use in the body.

- Miniaturization Expertise: Using advanced microfabrication methods, HITEC produce sensors small enough to integrate into constrained implant spaces without compromising performance.

- Biocompatible Packaging: Sensors are encapsulated in hermetically sealed, medically approved materials that meet FDA and ISO standards for long-term implantation.

- Proven Reliability: HITEC sensors undergo rigorous fatigue, temperature, and environmental testing, giving engineers confidence that performance will not degrade over time.

- Integration Support: Beyond sensor fabrication, HITEC provides industry leading guidance on adhesive bonding, calibration, and data acquisition strategies, reducing risk and accelerating development cycles.

By combining these capabilities, HITEC ensures that engineering challenges such as miniaturization, stability, power, and durability are directly addressed within the sensor design itself.

PARTNER WITH HITEC

FOR CUSTOM STRAIN GAUGE SENSORS

Custom strain gauge sensors are redefining how medical implants support healing. By measuring real-time loads and stresses during recovery, these sensors give clinicians and engineers critical insight into how the body and implant respond together. This data helps guide rehabilitation, reduce complications, and accelerate a patient’s return to mobility.

HITEC Sensors makes this innovation possible. Through advanced design, miniaturization, and biocompatible packaging, HITEC develops custom sensors that perform reliably within the body’s demanding environment. Every new sensor innovation aims to deliver faster, safer, and more effective patient healing.