In high-performance sensing applications, the difference between acceptable and exceptional often lies in manufacturing discipline.

At HITEC, our approach to strain-gauge transducer development is founded on precision mechanical design, rigorous bonding processes, advanced calibration, and continuous quality control.

Why Precision Manufacturing Matters

Strain-gauge transducers remain a backbone technology across force, torque and structural sensing domains. Yet the inherent physics, small deformation and minute resistance changes means that any weakness in the manufacturing chain (adhesive creep, misalignment, contamination) can degrade performance by orders of magnitude.

At HITEC, we view transducer manufacture not as a simple assembly but as a series of precision-controlled micro-processes, each of which contributes to stability, repeatability, and longevity.

The Engineering Science Behind Strain-Gauge Transducers

When a mechanical structure flexes under load, strain gauges bonded to its surface detect the tiniest stretch or compression. These gauges, typically made from metallic foil, change their electrical resistance in direct proportion to strain.

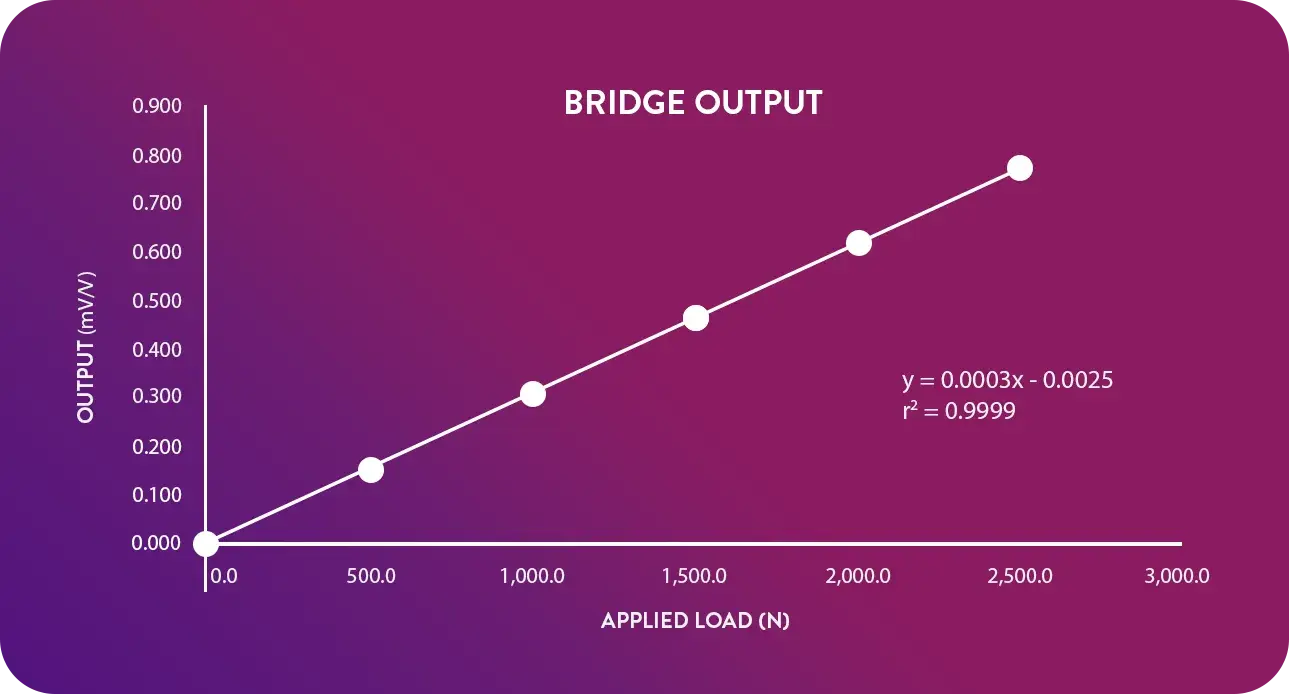

By wiring multiple gauges into a Wheatstone bridge, the transducer converts this resistance change into a small, proportional voltage output. That output, often measured in millivolts per volt (mV/V), becomes the precise representation of force, pressure, or torque applied.

Key takeaway: Mechanical precision drives electrical accuracy. Every transducer’s performance starts with the quality of its flexure design and gauge integration.

Designing the Flexure Where Precision Begins

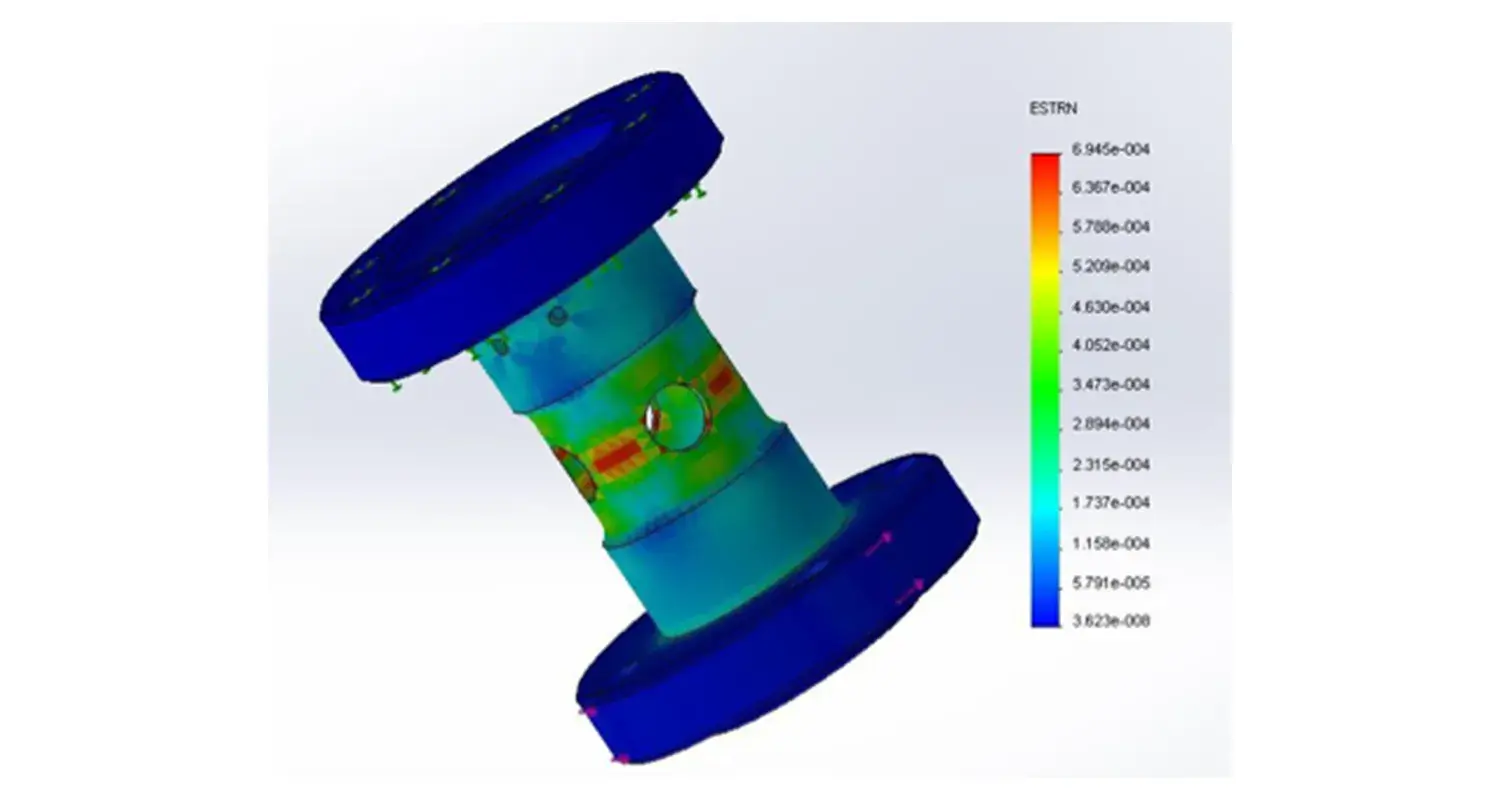

A transducer’s flexure (elastic element) determines how applied loads translate into measurable strain. At HITEC, our design process begins with finite element analysis (FEA), simulating real-world stress and strain distributions under load. This allows us to shape the flexure so that deformation occurs only in intended regions, minimizing unwanted crosstalk or nonlinearity.

Each design is optimized for:

- Predictable, repeatable strain distribution

- High fatigue life under cyclic loading

- Minimal hysteresis and thermal drift

- Compatibility with target materials (typically stainless or alloy steels)

The result is a mechanical platform tuned for accuracy before a single gauge is applied.

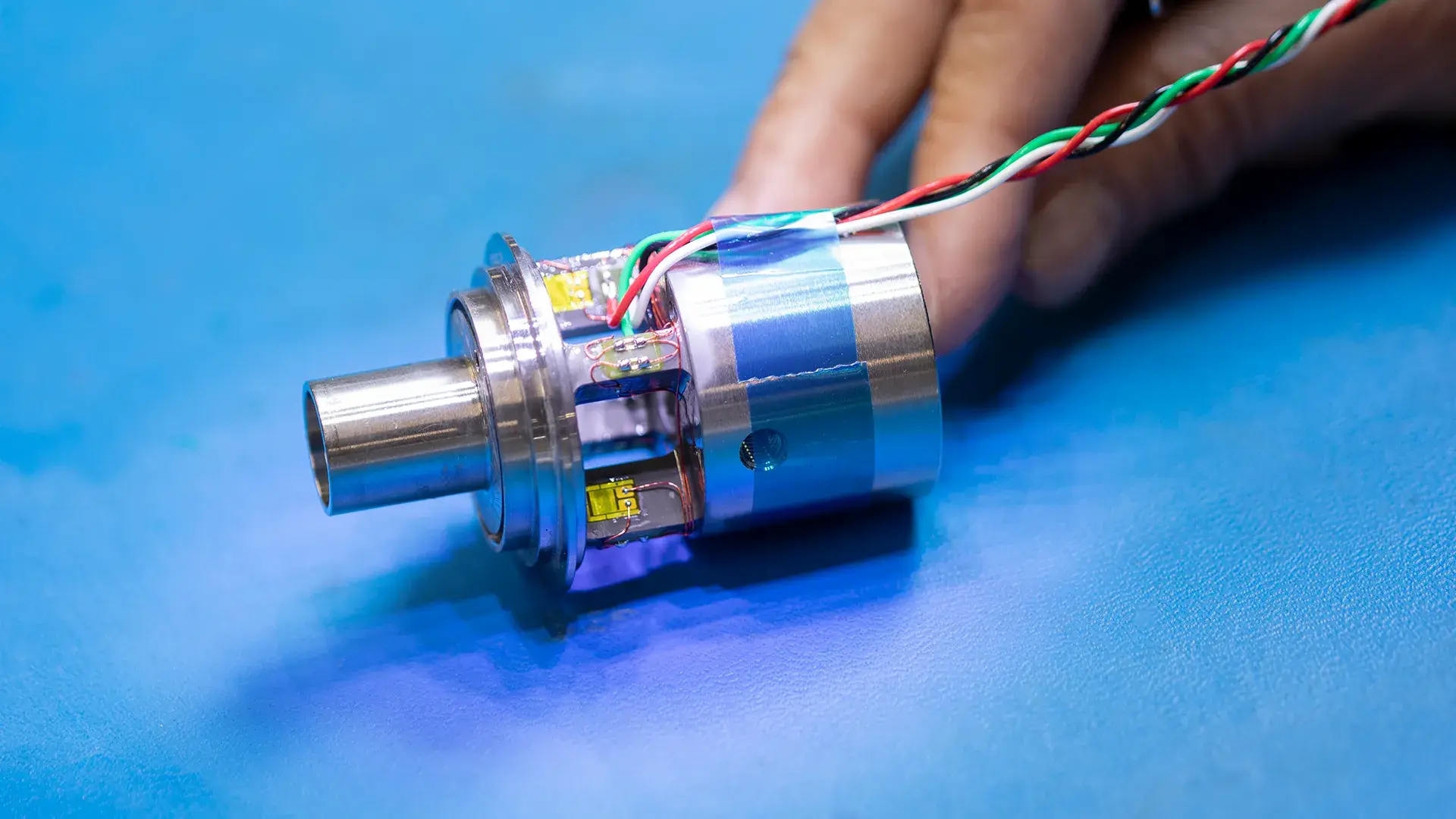

Strain Gauge Integration Micron-Level Manufacturing Precision

Bonding strain gauges to metal sounds simple, but it’s where precision becomes critical. A perfectly aligned, uniformly bonded gauge ensures accurate strain transfer and long-term stability; even microscopic imperfections can introduce error or creep.

HITEC’s bonding process involves:

- Surface preparation under controlled cleanroom conditions

- Application of high-stability adhesives designed for minimal creep and excellent temperature performance

- Precision alignment using optical tooling and fixturing

- Thermal curing and conditioning to stabilize the bond

- Protective encapsulation against moisture, vibration, and mechanical stress

This meticulous process transforms a raw flexure into a calibrated sensing element capable of detecting microstrains with repeatable accuracy.

From Electrical Assembly to Calibration

Once strain gauges are in place, HITEC engineers complete the bridge circuit, integrate temperature-compensation resistors, and pot or seal the assembly for environmental protection.

Then begins calibration, the step that translates raw output into meaningful data. Using traceable load standards and controlled conditions, each transducer undergoes:

- Static and dynamic calibration

- Temperature and creep characterization

- Fatigue and vibration testing

- Linearization and error analysis

The output is a detailed calibration certificate documenting the device’s sensitivity, linearity, hysteresis, and drift, ensuring every unit meets its specified performance envelope.

Quality Control and Traceability

HITEC’s production philosophy is simple: every transducer must perform as well in year five as it did on day one. That commitment is enforced through statistical process control (SPC) and full traceability of materials, processes, and operators.

Each production phase: bonding, wiring, potting, calibration, is validated through in-line inspection. Our engineers monitor key metrics like bridge balance, resistance, and drift behaviour using automated data capture, allowing for trend analysis and predictive quality management.

The result? Exceptionally low field failure rates and sensors trusted by OEMs and system integrators worldwide.

Field Reliability and Application Support

HITEC’s responsibility doesn’t end at shipment. We support our customers with:

- Custom mounting guidance and alignment checks to ensure accurate load transfer

- Periodic recalibration services and verification against certified standards

- Rapid repair and refurbishment for extended lifecycle management

Proper installation and ongoing calibration ensure that measurement integrity is maintained throughout the sensor’s service life, even in demanding applications like aircraft structural monitoring or robotic force feedback.

Innovation and the Future of Transducer Manufacturing

While the core physics of strain measurement haven’t changed, HITEC is shaping the future of transducer technology through innovation in materials and methods.

- Thin-film and direct-deposition gauges eliminate adhesive creep

- Additive manufacturing allows for customized, embedded sensing geometries

- Graphene and nanomaterial-based gauges promise higher gauge factors and flexibility

- Smart transducers integrate digital electronics, diagnostics, and wireless telemetry

These technologies enable faster response times and reduced sensor footprint, essential for next-generation robotics, aerospace, and autonomous systems.

HITEC Sensors Your Partner for Strain-Gauge Sensor Excellence

Precision measurement is never the result of a single breakthrough, it’s the sum of thousands of precise, repeatable decisions made across design, manufacturing, and testing. At HITEC, we combine engineering expertise, process control, and innovation to produce strain-gauge transducers that set the standard for accuracy and reliability.

Whether you need a custom force sensor for a robotic arm or a rugged load transducer for aerospace testing, HITEC delivers measurement integrity you can trust, engineered from the ground up.