In the ever-evolving world of additive manufacturing, continuous innovation is paramount. Companies are constantly seeking ways to enhance their processes, aiming for faster, larger, and more intricate print designs. To meet these dynamic challenges head-on, they need partners that understand their unique needs and can deliver tailor-made solutions. At HITEC Sensors, we are a leading name in the sensor industry, and have built a reputation grounded in innovation, quality and precision. HITEC are widely recognized as the experts in custom sensor design, particularly in the realm of custom load cells. One of our many success stories involves developing custom solutions for the additive manufacturing industry in order to create a ground-breaking 3D printer platform.

THE CHALLENGE WITH FORCE SENSING IN 3D PRINTING

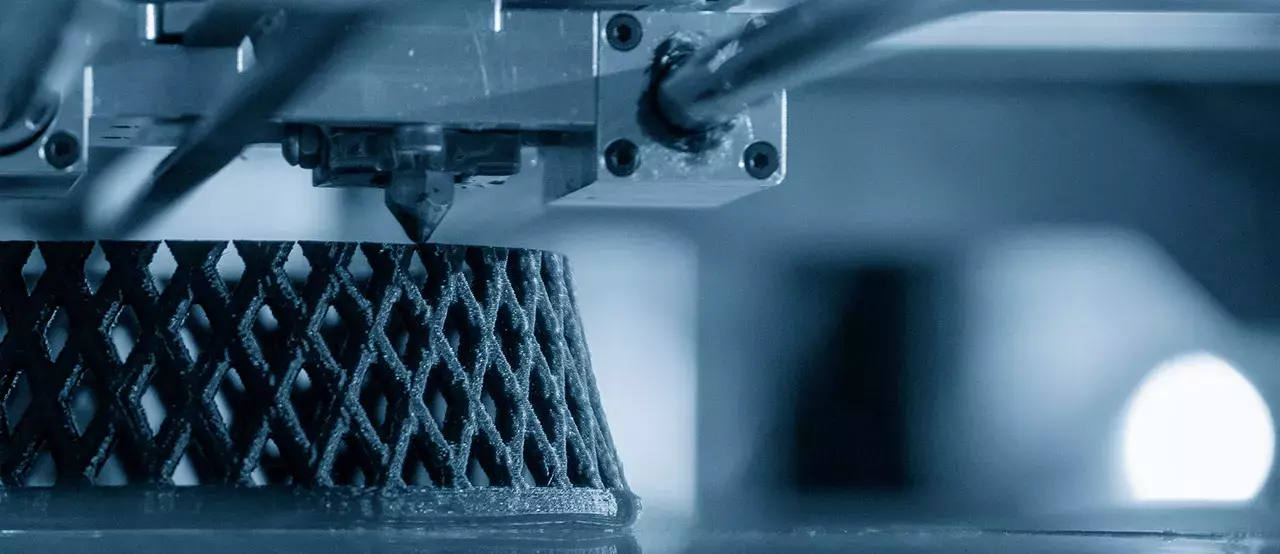

As the 3D printing industry increasingly demands printers capable of producing high-quality, durable prints with carbon fiber reinforcement. These such applications require two distinct print heads to work simultaneously together. One for common 3D printing materials such as ABS, PLA and other blends, and the other for laying down carbon fiber.

The challenge with this applications lies in monitoring the forces from both print heads simultaneously, a requirement beyond the capabilities of standard, off-the-shelf sensors due to its complexity.

This gap in the market presents an opportunity for innovation..

3D printing is achieved by the method of additive manufacturing, where materials are assembled layer by layer under digital guidance to form a three-dimensional object.

HITEC'S INNOVATION: CUSTOM DUAL-SIDED LOAD CELLS

At HITEC, we work closely with your engineering team to develop custom dual-sided load cell solutions capable of monitoring the forces at each print head. The sensor was designed to provide separate, independent, analog outputs. This custom sensor design was not only small and robust enough to meet the technical requirements of the application, but also cost-effective, ensuring the project's commercial viability.

Once integrated into a system, HITEC's custom load cells deliver performance and ensure proper media flow rate and guaranteed consistently high-quality printed parts with minimal waste.

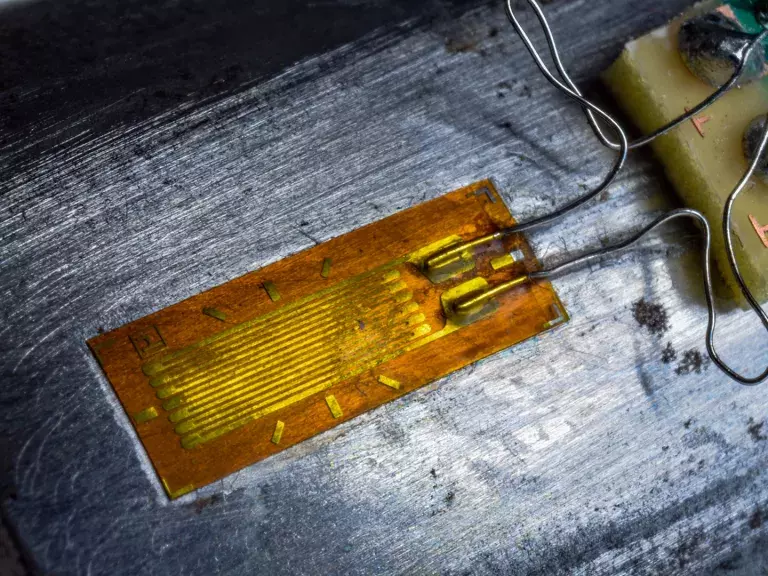

At HITEC, we specialize in custom strain gauge-based transducers. Designing and manufacturing all custom products in house, while supporting a global customer base, we aim to provide the best possible solution for every application we encounter.

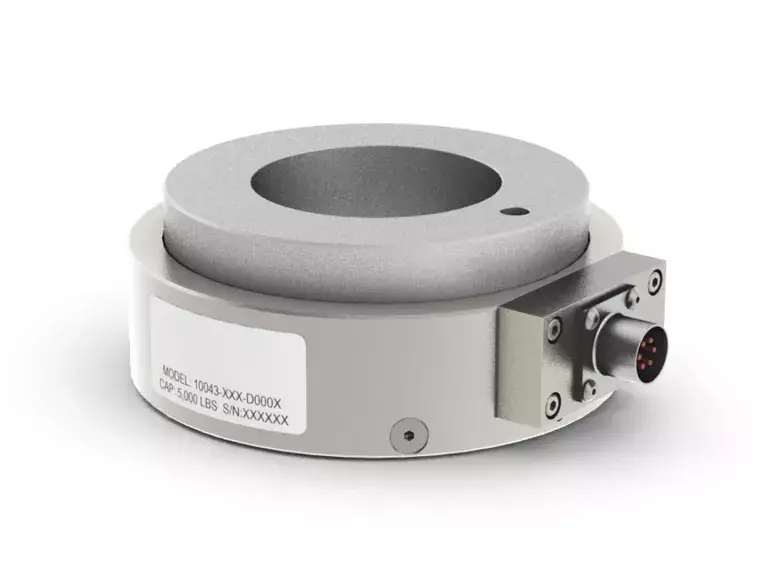

This is a compact, universal force sensor. This low profile unit has a small outer diameter and is capable of measuring both tension and compression.

The 10043 hollow pancake force sensor is designed to measure compression only loads. The 10019 is designed to measure tension and compression loads.

WHY USE CUSTOM SENSORS IN 3D PRINTING?

The benefits of utilizing custom dual-sided load cells in 3D printing applications are multifaceted and significant.

Enhanced Precision and Efficiency

Firstly, these specialized sensors allow for precise, real-time monitoring of forces applied by dual print heads, which is critical for maintaining the integrity and quality of complex prints, especially those requiring mixed materials. By enabling such detailed oversight, these load cells prevent the common issues of over or under-extrusion, thereby reducing material wastage and improving print fidelity.

Maximised Versatility

Furthermore, the customization aspect ensures that the load cells can be tailored to fit specific printer designs and performance requirements, offering a versatility that off-the-shelf sensors cannot match. This bespoke approach not only enhances the printer's functionality but also contributes to operational efficiency by optimizing the printing process and minimizing the need for post-production adjustments.

High Temperature Resistance

Additionally, the robust and compact design of these load cells ensures they can withstand the demanding environment of 3D printing, including exposure to high temperatures and mechanical stresses, without compromising their performance or accuracy. This durability translates into lower maintenance costs and extended equipment life spans, further improving the return on investment for manufacturers.

In summary, the integration of custom dual-sided load cells into 3D printing systems represents a smart investment in precision, efficiency, and reliability, directly contributing to superior print quality, reduced waste, and enhanced overall production efficiency.

Subscribe for Insights

Industry insights, trends, events and unmissable content straight to your inbox

Sign up to our newsletter to get insider access to stay up to date with all things custom strain gauge sensing

Innovation and customization are key drivers in the additive manufacturing industry, and HITEC Sensors is at the forefront of providing tailor-made solutions to meet these evolving needs.

HITEC Sensors' success in developing a custom dual-sided load cell for this complex application underscores their position as leaders in the field of custom sensor design. Customers can trust HITEC Sensors to deliver bespoke solutions that meet their unique needs, giving them a competitive edge in their respective industries.

Are you ready to elevate your capabilities with custom load cell solutions tailored to your specific needs? HITEC Sensors invites you to take the first step towards innovation and excellence. Complete the form below to discuss your project with our expert team and discover how our custom solutions can provide you with a competitive advantage.

Layer by layer, the material is seamlessly combined, whether it be liquid resin or powdered substances. This process can create many varieties of shapes, from the simplest to the most intricate designs, all originating from a digital 3D blueprint or CAD file.