Rehabilitation equipment plays a vital role in the post-injury or surgical recovery process. The integration of strain gauge sensors helps in advancing this technology by enhancing functionality, safety, and user experience of rehabilitation equipment such as rehabilitation bikes and mobility scooters. This article explores how custom strain gauge sensors are strategically integrated into these devices to measure various forces and strains and provide feedback.

WHY ARE STRAIN GAUGE SENSORS USED IN REBILITATION EQUIPMENT?

Strain gauge sensors measure force by detecting the changes in electrical resistance that occur whenever the material to which they are attached undergoes deformation due to applied force. The conversion of these resistance changes into real-time data allows for accurate monitoring and analysis of the forces exerted during activities.

This information facilitates personalized and effective rehabilitation programs, enabling healthcare professionals to monitor progress, ensure safety, and tailor interventions to meet the unique needs of each individual undergoing rehabilitation.

Subscribe for Insights

Industry insights, trends, events and unmissable content straight to your inbox

Sign up to our newsletter to get insider access to stay up to date with all things custom strain gauge sensing

STRAIN GAUGE SENSORS IN REHABILITATION BIKES

Rehabilitation bikes offer a controlled and targeted approach to rebuilding strength and endurance after injuries or surgeries. Among the technological advancements transforming these rehabilitation aids, strain gauge sensors stand out as a pivotal innovation. Embedded strategically into the intricate components of rehabilitation bikes, these sensors provide a granular understanding of the forces and strains experienced by users during their exercise regimens. Below are some examples of how strain gauge sensors are installed into rehabilitation bikes and how they are used.

PEDAL FORCE MEASUREMENT

Strain gauge sensors are integrated into the pedal mechanism of rehabilitation bikes to provide an understanding of the force exerted by users during pedalling. This data serves as a quantitative indicator of the strength and endurance of lower limbs, enabling therapists to tailor exercise regimens that align with individual progress. The real-time feedback empowers both therapists and users to make informed decisions about the intensity and duration of rehabilitation sessions.

HANDLEBAR AND SEAT STRAIN MONITORING

Beyond lower limb assessment, strain gauges are strategically placed on handlebars and seats to monitor user posture and grip strength. This dynamic information contributes to the ongoing optimization of the rehabilitation bike's ergonomics, ensuring that users maintain proper body alignment throughout their sessions. The integration of strain gauges in these key areas not only enhances comfort but also aids in preventing potential musculoskeletal issues that may arise from improper positioning.

RELATED PRODUCTS

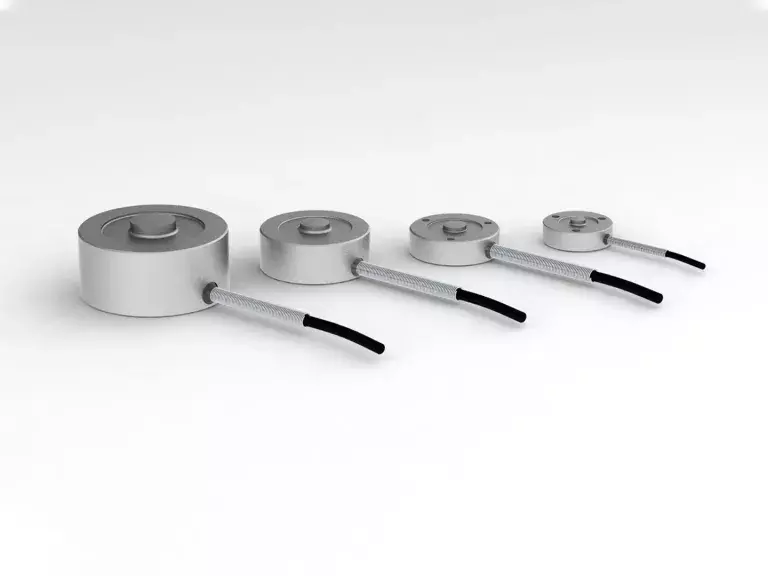

Button Load Cell

Button Load Cells are strain gage based transducers with temperature compensation and excellent overall performance.

In-Line Load Cell

Miniature Threaded in Line Load Cells are strain gauge based transducers with temperature compensation and excellent overall performance.

Custom Transducer Designs

We have the experience and expertise to provide custom products that meet the exact requirements of your application.

STRAIN GAUGE SENSORS IN MOBILITY SCOOTERS

Mobility scooters serve as critical equipment aids for individuals with limited mobility, offering a sense of independence and freedom. Custom strain gauge sensors can be strategically integrated into various components of mobility scooters to give feedback data on the forces and strains on the equipment. These sensors play an important part in enhancing load distribution, monitoring seat and armrest strains, and fortifying safety features.

LOAD DISTRIBUTION

In mobility scooters, strain gauges are embedded in structural components, such as the frame or wheels, to measure load distribution. This application is particularly critical in heavy-duty mobility scooters, where understanding and optimizing load distribution is essential for ensuring stability and structural integrity. Strain gauge data in this context contributes to the design of more robust and reliable mobility solutions.

SEAT AND ARMREST STRAIN MONITORING

Strain gauges on seats and armrests in mobility scooters serve a dual purpose. They not only monitor the distribution of the user's weight, providing real-time feedback on seating comfort, but also contribute to the design of more supportive and customizable seating arrangements. This personalized approach addresses the diverse needs of individuals with limited mobility, promoting a more comfortable and enjoyable mobility experience.

SAFETY FEATURES

The integration of strain gauges in mobility scooters extends to safety systems that detect unusual forces or impacts. This ensures a heightened level of safety by triggering mechanisms such as automatic speed reduction or braking in response to potential risks. By incorporating strain gauge sensors into safety features, mobility scooters prioritize user safety, providing individuals with increased confidence and peace of mind during their daily activities.

READ MORE

STRAIN GAUGE SENSORS FOR THE MEDICAL INDUSTRY

The integration of strain gauge sensors into rehabilitation equipment marks a transformative step in the evolution of mobility assistance and recovery technologies. Whether in rehabilitation bikes or mobility scooters, these sensors provide precise measurements of forces and strains, fostering a deeper understanding of user needs and progress. As technology continues to advance, the ongoing integration of strain gauge sensors promises continuous improvement in the realm of rehabilitation, promoting enhanced mobility, comfort, and safety for individuals on their journey to recovery.

With over five decades of experience, HITEC Sensors’ proficiency in medical sensor technology is unparalleled. We specialize in tailor-made engineering and manufacturing, uniquely positioning us to comprehensively address the requirements of medical equipment manufacturers. Our commitment extends to delivering highly personalized solutions in large quantities, produced, installed, and serviced either domestically or internationally. This approach ensures optimal pricing and timely delivery for a diverse range of applications.

Want to know more? Get in touch with our expert team to discover how HITEC can make a difference to your business with our market leading range of standard and custom strain gauge sensors.

Speak to our experts

Provide us with your information and our team will contact you

Chris Delling

Chris Delling is Field Sales Manager at HITEC Sensors with expertise in strain-gauge based force and torque sensors. With over 35 years experience in the field as well as industry experience in the construction and agriculture markets, Chris has a passion for sensor design and developing custom solutions.