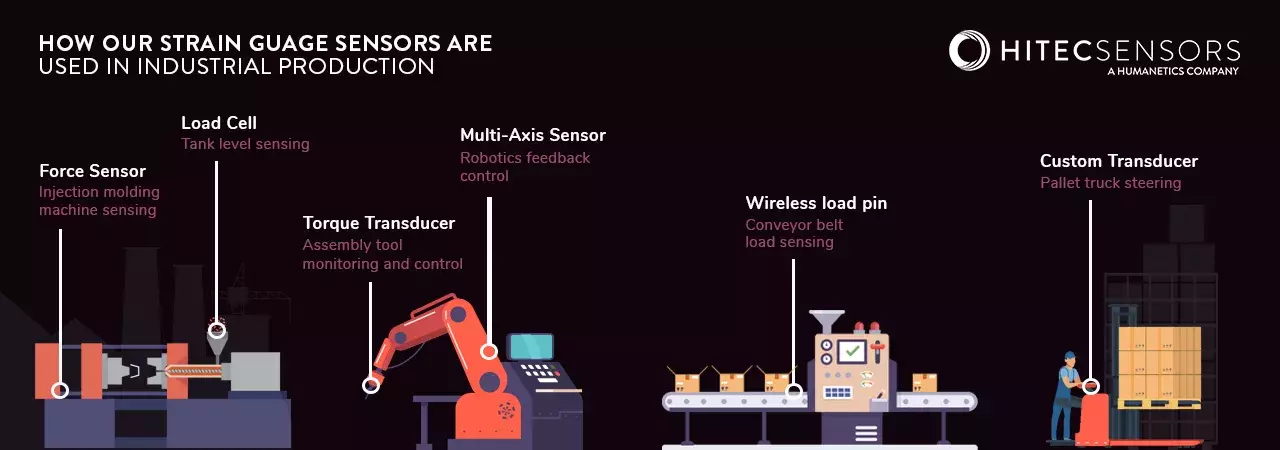

Sensors for the Industrial Market

The industrial market is broadly categorized as applications involving automation, manufacturing, or process control. HITEC has been supporting the industrial market for a half-century with custom sensors and instrumentation services.

How are Sensors used within Manufacturing?

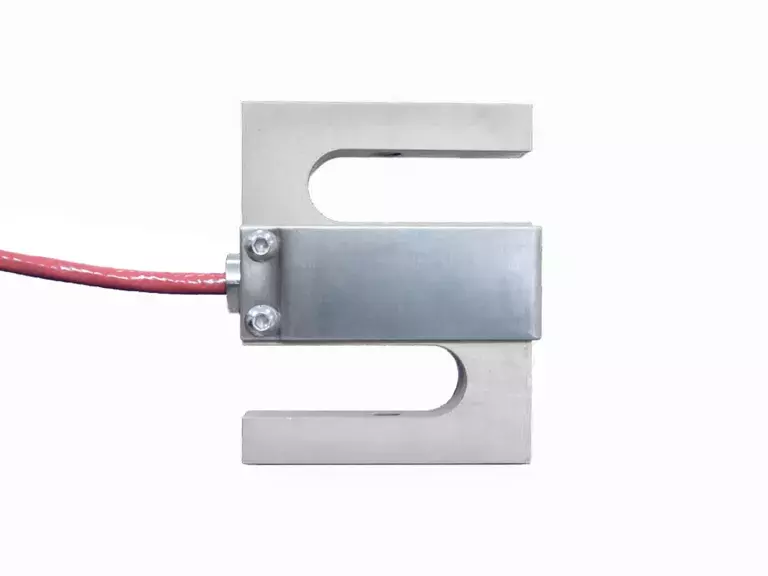

Load Measurement Sensing

Load measurement sensing using strain gauge sensors is a common method of measuring the weight or force applied to an object or structure. Strain gauge sensors work by detecting the strain, or deformation, of a material in response to a load, and converting this strain into an electrical signal that can be measured and analyzed. The strain gauge sensor is typically bonded to the surface of the object or structure, and as the load is applied, the strain gauge experiences a change in resistance that can be measured using a Wheatstone bridge circuit. Load measurement sensing using strain gauge sensors is widely used in engineering, manufacturing, and construction applications where the accurate measurement of force or weight is critical.

Related Products

Torque Measurement Sensing

Torque measurement sensors are devices designed to accurately measure the amount of torque applied to a rotating shaft or axis. They are commonly used in industrial applications where torque is a critical parameter, such as in manufacturing and engineering processes. These sensors typically use strain gauges to detect changes in the twisting force on the shaft, and convert these changes into an electrical signal that can be measured and recorded. Torque sensors can be used for both static and dynamic measurements, and are available in a range of sizes and capacities to suit different applications. Accurate torque measurement is essential for ensuring the safety, reliability, and efficiency of mechanical systems, and torque sensors play a vital role in achieving these goals.

Related Products

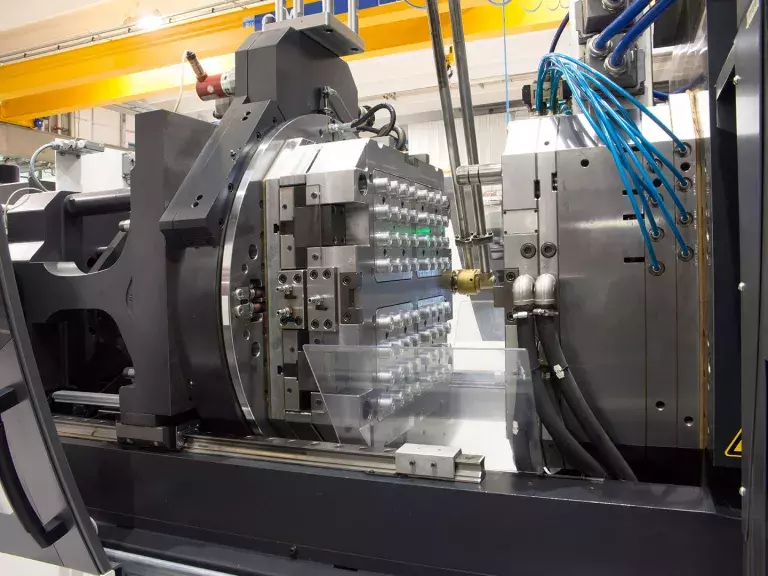

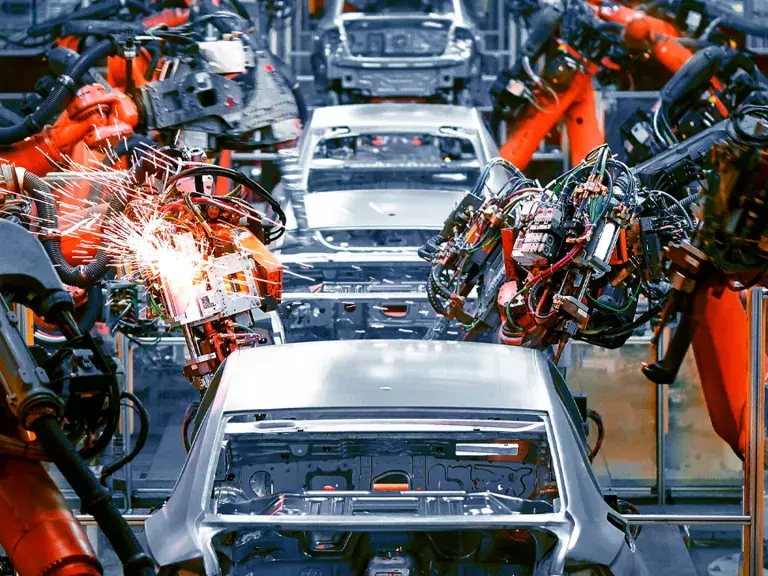

Robotic Welding Applications

One of the major contributors to the quality of a spot weld is clamping force. This clamping force is typically audited by a technician, making periodic measurements of the weld force using a hand-held instrument. However, since the robot’s motions and cycles are programmable, it is possible to specify a “check cycle” at regular intervals. As part of their programming, weld robots periodically move the weld tips into a tip dresser that grinds them into the optimum shape. Once this process is complete, the weld robot can be instructed to move to a check station, where it momentarily clamps down on a sensor that measures clamping force. The weld robot check station has memory on board that can hold thousands of measurements.

HITEC Innovations

With over 50 years of experience in custom-sensing solutions accompanied by our exhaustive library of application designs, one-offs and high-volume productions, HITEC are one of the leading experts in the Sensor industry and we aim to provide the best possible solution to every application we work on.

Below are just a few examples of our engineered solutions for the industrial market. Get in touch with us to discuss your custom requirements.