What is Injection Molding?

Injection molding is a versatile manufacturing technique employed in virtually every major sector of the industry, including medical, industrial, automotive, electronics, and consumer products. Its ability to produce complex shapes with high precision and efficiency has made it a popular choice across diverse applications. However, despite its apparent simplicity, the process of injecting molten plastics into a mold requires meticulous process controls to ensure optimal results. Without adequate monitoring and regulation, the quality of the final product may suffer, leading to issues such as dimensional inaccuracies, surface defects, or structural weaknesses. Moreover, the absence of proper process controls can result in significant scrap costs, as defective or non-conforming parts may need to be discarded. Therefore, it is essential to implement robust process controls, encompassing factors like temperature, injection pressure, cooling time, and material consistency, to maintain high-quality standards, minimize waste, and maximize the efficiency and profitability of the injection molding process.

How are Force Sensors used in Injection Molding?

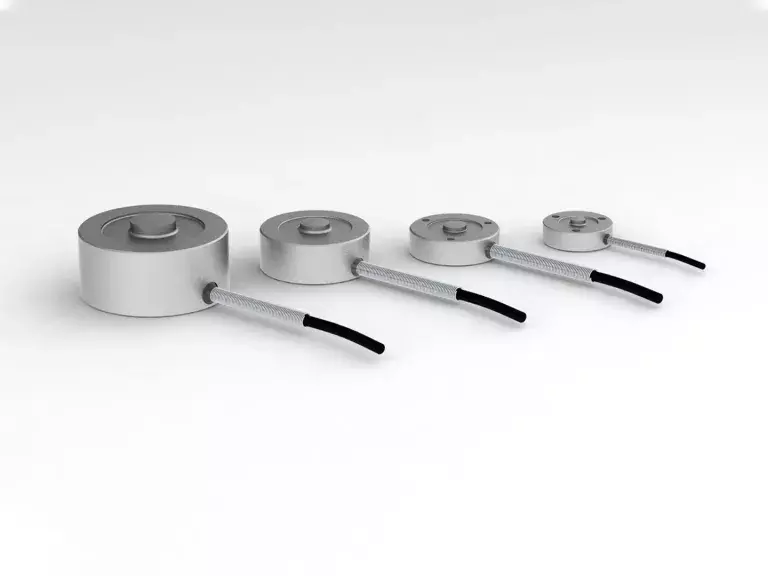

In the injection molding industry, the integration of force sensors offers a valuable solution for real-time, closed-loop control of the molding process. By incorporating miniature in-cavity mold pressure sensors at strategic positions within the mold, specifically placed behind the ejector pins, it becomes possible to precisely monitor the force exerted on the ejector pins. This innovative technology grants the ability to gain insights into the internal dynamics of the mold, enabling operators to visualize and understand the ongoing processes during each molding cycle.

The information provided by these force sensors empowers operators to identify and address potential issues promptly, thereby mitigating problems that could lead to defects and subsequent scrap or rework costs. By continuously monitoring the force exerted on the ejector pins, the sensors can detect anomalies such as short shots (incomplete filling of the mold), galley blockages (material flow restrictions), or overfills (excessive material injection). Armed with this real-time data, operators can make immediate adjustments to optimize the molding parameters, ensuring consistent part quality, minimizing waste, and reducing the need for costly rework or scrapping of defective parts.

The integration of force sensors in injection molding not only enhances process control but also facilitates proactive measures to maintain high production efficiency and profitability. By leveraging the insights provided by these sensors, manufacturers can improve their overall productivity, reduce waste, enhance product quality, and ultimately optimize their operations in the highly competitive injection molding industry

HITEC's Installation Capabilities

At HITEC, our team of highly skilled application engineers specializes in strain gauge installation, bringing years of industry experience and expertise to every project. We pride ourselves on our ability to employ state-of-the-art techniques and cutting-edge technologies to ensure the highest quality and reliability in strain gauge load cell installation.

With a deep understanding of strain measurement principles and a meticulous approach, our engineers possess the knowledge and precision required to install strain gauges effectively on a wide variety of surfaces. Whether it's on metals, composites, or other materials, we have the expertise to handle diverse applications and ensure accurate and consistent strain measurements.

We recognize the critical role that strain gauges play in a wide range of industries, from aerospace and automotive to manufacturing and research. That's why we are committed to providing our customers with the utmost support, delivering top-notch strain gauge installations that meet their specific requirements.

When you partner with HITEC, you can expect not only superior technical skills but also a dedicated team that values customer satisfaction. We strive to establish long-lasting relationships by providing reliable and high-quality strain gauge installations that enable precise measurement, robust data acquisition, and informed decision-making for your applications.

Choose HITEC for strain gauge installation services that combine technical excellence, industry expertise, and a commitment to meeting your needs with unparalleled quality and reliability.