How are Strain Gauges used in Aerospace?

Strain gauges play a vital role in the aerospace industry, enabling engineers to accurately measure and monitor the structural integrity of aircraft components. These small, flexible sensors are designed to detect and quantify the strain, or deformation, experienced by materials under various mechanical loads. In aerospace applications, strain gauges are strategically installed on critical components such as wings, fuselage, landing gear, and engine parts. By measuring the minute changes in electrical resistance resulting from mechanical deformation, strain gauges provide invaluable data on the performance, durability, and safety of these components. This data is then used to optimize designs, detect potential failures or fatigue, and ensure the overall structural integrity of aerospace systems.

Problems with Installing Strain Gauges on Aircraft

Installing a strain gauge onto an airplane presents several significant challenges to the installer. Below are just some of the challenges facing service engineers;

Aircraft Design: The complex and intricate nature of aircraft structures creates a challenging environment for strain gauge installation. The limited space, irregular shapes, and intricate geometries of various components make it difficult to identify suitable locations for strain gauge installation.

Adhesion Reliability: Ensuring proper adhesion and bonding of the strain gauge to the surface of the component can be challenging due to factors such as varying material properties, surface irregularities, and exposure to extreme temperatures and vibrations.

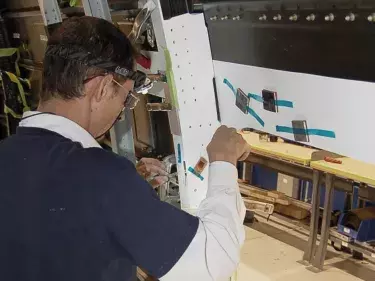

Ensuring Precision: The aerospace industry demands high levels of accuracy and reliability, which means that the strain gauge installation must be performed with meticulous precision. Even the smallest errors in placement or bonding can compromise the accuracy of strain measurements. The installation process itself often requires specialized expertise, tools, and techniques, adding complexity and time to the overall aircraft manufacturing or maintenance process.

If installation of strain gauges is performed in a substandard way, this can cause the gauges to be lifted off the surface of the airframe. This can result in inaccurate measurements, data variability, premature failure, safety risks, and increased costs and downtime. Therefore, it is crucial to ensure proper installation techniques and adhere to industry best practices when working with strain gauges in aerospace applications.

HITEC Solutions

At HITEC, we take pride in offering comprehensive on-site services to our aerospace customers. Through our personalized approach, we visit worksites, thoroughly review the project scope, and gain an in-depth understanding of our customers' processes and challenges. This hands-on approach allows us to tailor our solutions to meet their specific requirements and schedules, ensuring a seamless experience.

With our extensive industry experience, we possess the expertise to identify and rectify issues arising from poorly installed strain gauge systems. Our skilled technicians and engineers are equipped to remove and replace faulty gauges, ensuring the installation of fully functioning strain gauges.

In addition to our service technicians, our knowledgeable engineers are readily available to provide on-site support and supervision throughout the duration of our customers' projects. We work closely with them to address any concerns, offer guidance, and ensure successful project completion.

At HITEC, we understand the importance of meeting aggressive timelines in the aerospace industry. Our dedicated team is committed to supporting our customers' schedules, allowing us to successfully install hundreds of strain gauges on aircraft empennage and wings. Thanks to our meticulous approach and attention to detail, we take pride in achieving a track record of zero failures, delivering reliable and accurate strain gauge installations.