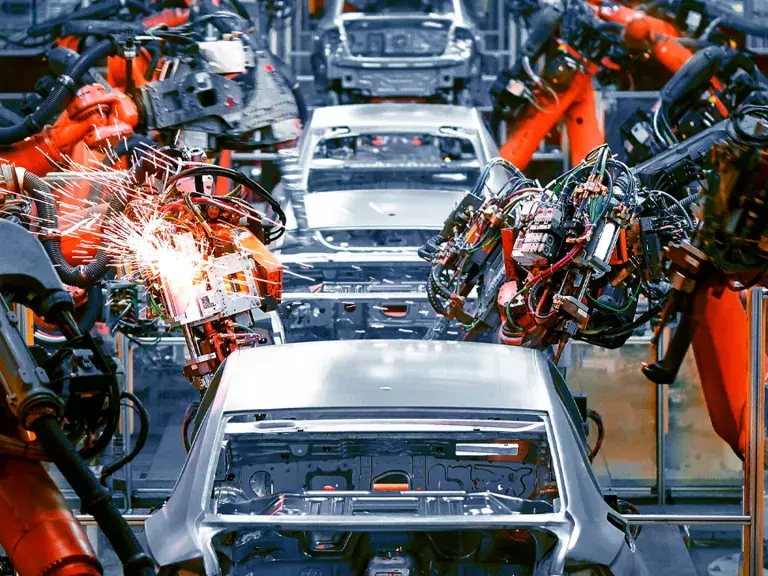

An elaborate stage is an integral part of the modern entertainment venue, such as for a play or concert, and rigging plays an important role in creating the right environment.

These huge, temporary structures are put together with thousands of components, many of which are overhead. Monitoring the load and distribution of weight is important for ensuring a safe environment for both the performers and the audience. An overloading situation can result in a collapse which could lead to injuries or even death. 32 million people attend at least one U.S. music festival each year, and over the years there have been thousands of injuries due to collapse of stage equipment and rigging.

What is a Load Pin?

A load pin, also known as a load sensing pin or load cell pin, is a specialized mechanical component used for measuring and monitoring the load or force applied to it. It is commonly used in various industrial and engineering applications where it's important to accurately determine the force or load being exerted on a particular part of a machine, structure, or system.

How does a Load Pin work?

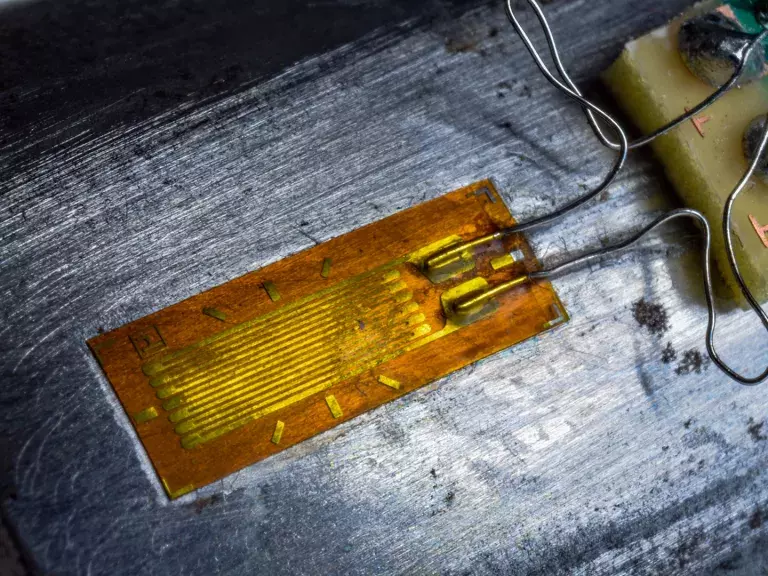

A load pin works based on the principles of strain measurement. When a force or load is applied to the load pin, it undergoes deformation, and this deformation is measured using strain gauges. Load pins are typically designed as cylindrical or rod-shaped components with a central hole. They are often made of materials like stainless steel or alloy steel to ensure durability and resistance to environmental conditions.

Strain gauges are attached or embedded onto the surface of the load pin. Strain gauges are electrical devices that change resistance when subjected to mechanical deformation. When the load pin undergoes stress or strain due to an applied force, the strain gauges experience a change in resistance. The strain gauges are usually arranged in a Wheatstone bridge configuration.

A Wheatstone bridge is a circuit that allows for the measurement of small changes in resistance. As the load pin deforms under load, the resistance of the strain gauges changes, causing an imbalance in the bridge. The imbalance in the Wheatstone bridge generates a small electrical signal proportional to the applied force. This signal is typically in the millivolt range and needs to be amplified for further processing.

The small millivolt signal is amplified and conditioned using electronic circuits. This is necessary to ensure that the signal is strong enough for accurate measurement and can be transmitted over longer distances without significant loss. The conditioned signal is then transmitted to a data acquisition system or monitoring device. This system can convert the electrical signal into a digital value that represents the applied load. The digital load data can be used for various purposes, such as monitoring, control, safety, or data recording.

Subscribe for Insights

Industry insights, trends, events and unmissable content straight to your inbox

Sign up to our newsletter to get insider access to stay up to date with all things custom strain gauge sensing

Solving Problems with Load Pin Solution

HITEC works with many electronics organisations, helping to supply complete multi-channel systems that provide continuous load monitoring and real time feedback for various application such as stage rigging. Working with our customer’s engineering teams and incorporating feedback directly from end-users, we are able to design custom load pins that are able to monitor loads up to 5 tons. These load pins are suitable for use in both indoor and outdoor environments and have integrated electronics which wirelessly transmitted real-time signals to a base station, where the data can then be easily displayed, monitored and logged.

With the unique design and robustness, HITEC Load pins are recommended in a wide range of force, load and constraint measurement applications under various environments typical for industrial, agricultural, medical, automotive, marine, and aeronautical sectors.

Our load pin features;

- Rated capacity range up to 200kN.

- Optional IP ratings including hermetically sealed versions.

- mV/V output and inbuilt signal conditioning electronics on demand (amplified 4-

- 20mA current loop, voltage output options and CANOpen/MODBUS output)

- Cable and connector versions upon customer demand

- Wireless and Bluetooth communication options.